When you’re tasked with mitigating air pollutants like ozone, carbon monoxide, VOCs, or ethylene oxide, choosing the right catalyst isn’t just a technical decision—it’s a regulatory, operational, and financial one. That’s where Carus’ CARULITE® catalyst solutions come in. With options tailored to specific pollutants, operating conditions, and substrate configurations, CARULITE products help streamline emissions control in industries ranging from healthcare to water treatment.

This guide walks you through the process of selecting the best CARULITE catalyst for your application by explaining the chemistry behind each product, reviewing typical use cases, and following a straightforward decision-making checklist.

Table of Contents

Understanding the Challenge: Pollutant Control Isn’t One-Size-Fits-All

Air pollution control systems must meet strict emissions standards, often targeting specific contaminants under challenging conditions—high humidity, variable temperatures, and tight spatial constraints. Each pollutant poses unique risks:

- Ozone (O₃): While useful in water treatment and disinfection, excess ozone in off-gas must be destroyed before venting due to its harmful respiratory effects and role as a greenhouse gas.

- Carbon Monoxide (CO): Present in breathing air systems, cryogenic separation, and industrial exhausts. Colorless, odorless, and lethal in high concentrations.

- Volatile Organic Compounds (VOCs): Includes formaldehyde, alcohols, and other hydrocarbons often found in indoor air or industrial off-gassing. Regulated for their health risks and contribution to smog.

- Ethylene Oxide (EtO): Widely used for sterilizing medical equipment, EtO is a potent carcinogen with stringent EPA and OSHA regulations for emissions.

Trying to control all of these with a single catalyst? That’s a recipe for inefficiency. Each pollutant has a different reactivity profile—and that’s where the CARULITE catalysts excel.

Product Summary: CARULITE® 200, 300, 400, and 500

Each CARULITE catalyst has been engineered and refined over 30 years of application experience, for a specific set of pollutants and operational conditions. Here’s a breakdown:

CARULITE® 200

- Target pollutant: Ozone

- Typical applications: Off-gas from ozone disinfection in water treatment, laboratory exhausts, corona treaters and non-thermal plasma generators

- Operation: Works at ambient temperature; no external heat required

- Form: Granular

- Key advantage: Converts ozone safely to oxygen with no byproducts

CARULITE® 300

- Target pollutant: Carbon Monoxide

- Applications: Industrial compressed air systems, cryogenic air separation, personal respirators, aircraft cabin and subsea breathing air systems

- Operation: Ambient or slightly elevated temperatures

- Form: Powder and granular

- Key advantage: High activity for CO oxidation with minimal pressure drop

CARULITE® 400

- Target pollutants: Ozone and VOCs (e.g., formaldehyde, ethanol, acetaldehyde)

- Applications: Indoor air quality, cleanrooms, consumer electronics

- Operation: Ambient temperature; applied to metallic, ceramic, or fiber-based media

- Form: Powder catalyst

- Key advantage: Dual-function catalyst + flexibility in deployment

CARULITE® 500

- Target pollutant: Ethylene Oxide (EtO)

- Applications: Medical sterilization exhaust, pharmaceutical manufacturing

- Operation: Requires catalytic oxidizer (typically > 260°C)

- Form: Granular

- Key advantage: Extremely high EtO destruction efficiency (~99.99988%)

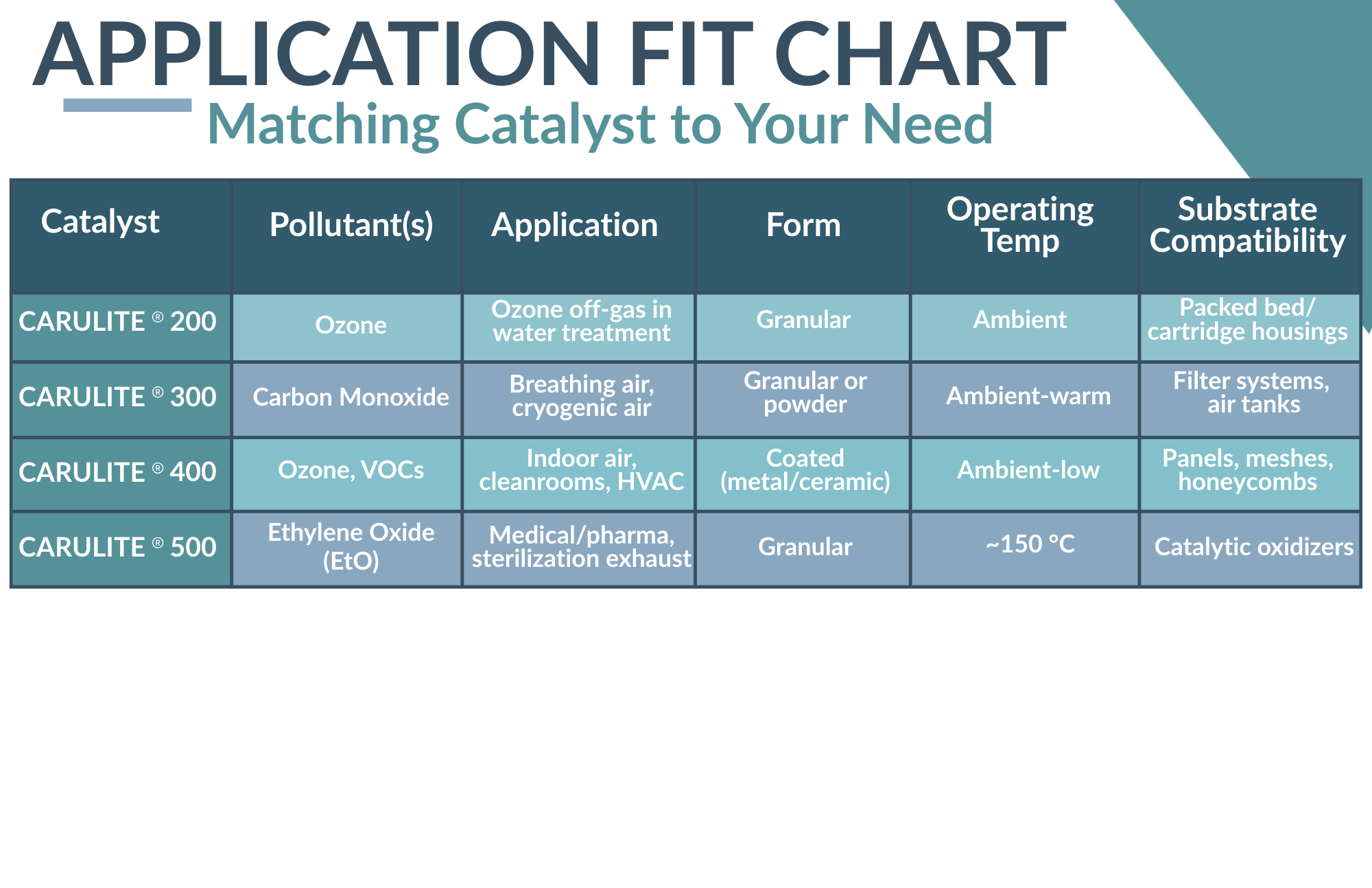

Application Fit Chart: Matching Catalyst to Your Need

Let’s compare your options side-by-side:

Substrate Options and Compatibility

Your choice of substrate directly affects pressure drop, residence time, and integration into existing systems. Among the CARULITE line:

CARULITE 400 is the most flexible, designed to be coated onto multiple substrates:

- Metallic honeycomb: For high-durability and FR-rated applications with low pressure drop

- Cellulose foams: For high surface area and low cost applications

- Non-woven fabrics: Ideal for lightweight HVAC filters

CARULITE 200, 300, and 500 are typically used in granular form, loaded into:

- Packed bed reactors

- Filter cartridges

- Gas scrubber canisters

Be sure to consider compatibility with corrosive gases, temperature stability, and space constraints when selecting your substrate.

Use Cases by Catalyst Type

Here’s how real-world users implement each CARULITE catalyst:

- CARULITE 200: Used by municipal water treatment facilities to treat ozone-laden off-gas from disinfection systems before venting. Zero maintenance and passive operation. In addition emerging non-thermal plasma applications require ozone by-product cleanup.

- CARULITE 300: Deployed in industrial cryogenic air separation units to eliminate CO, protecting sensitive equipment downstream. In addition, used in compressed breathing applications such as hospital and scuba oxygen tanks and in fire and mine safety rescue masks.

- CARULITE 400: Found in various indoor air quality improvement applications ranging from large air-handling system filters to smaller consumer focued air purification devices. Designed to remove formaldehyde and residual ozone improving IAQ for commercial, institutional and residential needs.

- CARULITE 500: Employed in sterilization plants to meet stringent EtO emission standards—achieving 99.99988% destruction efficiency, as reported in a case study from a large medical sterilizer.¹

Decision Checklist: Choose Your Catalyst Wisely

When deciding which CARULITE catalyst to select, ask yourself:

- What pollutant(s) are you targeting?

- Ozone → 200 or 400

- CO → 300

- VOCs → 400

- EtO → 500

- What’s your application environment?

- Ambient or low temp → 200, 300, or 400

- High-temp oxidizer → 500

- Do you have space or form factor constraints?

- Need coated media → 400

- Can use granular beds → 200, 300, 500

- How often can you maintain or replace media?

- All CARULITE catalysts offer long service life, not being affected by targeted VOC destruction, but are subject to in service poisoning from environmental contaminants. Contact your Carus sales representative for questions regarding specific service life questions.

- All CARULITE catalysts offer long service life, not being affected by targeted VOC destruction, but are subject to in service poisoning from environmental contaminants. Contact your Carus sales representative for questions regarding specific service life questions.

- Are you meeting regulatory requirements (EPA, OSHA, etc.)?

- CARULITE catalysts are proven to help meet stringent emission standards, especially for EtO.

- CARULITE catalysts are proven to help meet stringent emission standards, especially for EtO.

If in doubt, Carus’s technical team offers product selection support tailored to your setup. Contact us at (815) 223-1500.

Wrapping Up: A Catalyst for Every Challenge

No matter what air pollutant you’re dealing with, Carus’s CARULITE catalyst line has a targeted solution designed to maximize efficiency, meet environmental standards, and minimize maintenance. By aligning your pollutant type, process conditions, and system design with the right CARULITE catalyst, you’re setting your operation up for long-term regulatory compliance and operational peace of mind.

And remember: it’s not just about picking a catalyst—it’s about choosing a reliable partner in clean air. With over 100 years of chemical innovation and more than 30 years of practical application history, Carus is more than just a manufacturer. We’re a long-term ally in environmental responsibility.

¹ Case study citation: “Catalytic Destruction of Ethylene Oxide in Sterilization Exhaust.” AZoM.com