BACKGROUND

Kootenai-Ponderay Sewar District located near Sandpoint, Idaho, was trying to control hydrogen sulfide corrosion and odor at two lift stations and several manholes. The source of the problems was from a pressure sewer line that was being discharged into a gravity line below a manhole. The

pressure sewer line consists of discharge from a STEP System (septic tank effluent pump). It was determined that the best point for applying odor control chemical was at the injection station located over a valve box of the pressure line. This location was 300 feet before the pressure line

discharged into the gravity line.

EVALUATION/APPLICATION

Due to the very short reaction time allowed, a chemical that would provide almost immediate odor control was required. Additional constraints included limited space for chemical feed equipment, and the need for a simple system that required minimal manpower. Based on the information

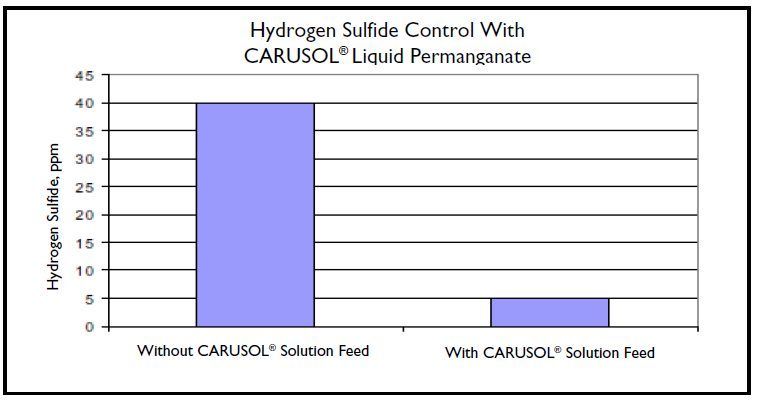

provided, Carus recommended the use of CARUSOL® Liquid Permanganate. CARUSOL was diluted from approximately 12% to 7% and was fed by a peristaltic pump at the injection station. Hydrogen sulfide levels that were averaging 40 ppm, determined by data logging H2S monitors, were

immediately reduced to less than 5 ppm (shown below). Odors that had been a problem at the lift stations and manholes were eliminated.

CONCLUSIONS

• Controlled hydrogen sulfide and other odors

• Reduced corrosion

• Significantly reduced residential complaints

• Provided a safe, simple, easy to installand effective solutin to a common municipal problem